Info

Archives

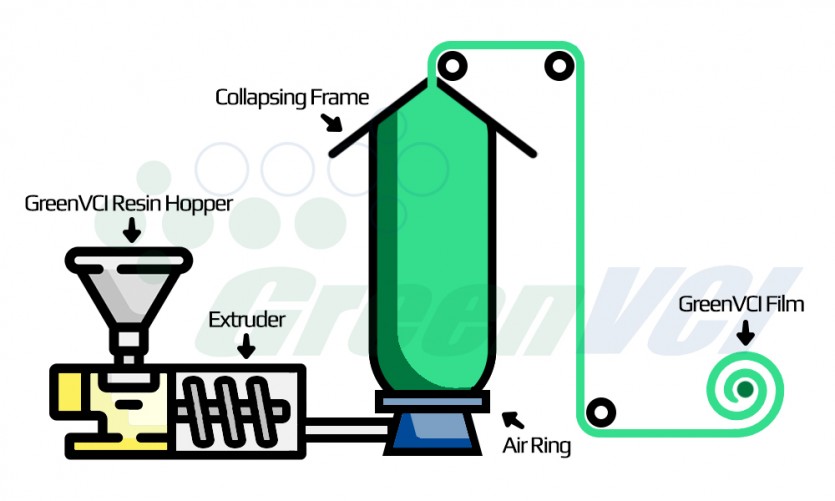

How VCI Films are Made

2023.05.17

The VCI (volatile or vapor corrosion inhibitor) masterbatch is a concentrated form of VCI that can be added to plastic films during the manufacturing process to create VCI films. Its compounds would release into the surrounding environment to prevent rust and corrosion on metal surfaces.

The process for making VCI films using VCI masterbatch involves the following steps:

1. Resin mixing: The resin (usually polyethylene) and VCI masterbatch (at around 5%) are mixed together in a hopper.

2. Extrusion: The resin mixture is then fed through an extruder, which melts and shapes the plastic into a thin film.

3. Cooling and winding: The film is cooled with water and then wound onto large rolls.

The VCI masterbatch is added to the resin during the mixing process and is evenly distributed throughout the plastic. This ensures that the corrosion inhibitors are present throughout the film and will be released when the film is used to protect metal surfaces.

Using VCI masterbatch has several advantages over adding VCI directly to the base polymer. It allows for more precise control over the concentration of the corrosion inhibitors and can reduce the risk of inconsistent mixing. Additionally, it can simplify the manufacturing process and reduce the amount of VCI needed to create the desired level of protection.

The process for making VCI films using VCI masterbatch involves the following steps:

1. Resin mixing: The resin (usually polyethylene) and VCI masterbatch (at around 5%) are mixed together in a hopper.

2. Extrusion: The resin mixture is then fed through an extruder, which melts and shapes the plastic into a thin film.

3. Cooling and winding: The film is cooled with water and then wound onto large rolls.

The VCI masterbatch is added to the resin during the mixing process and is evenly distributed throughout the plastic. This ensures that the corrosion inhibitors are present throughout the film and will be released when the film is used to protect metal surfaces.

Using VCI masterbatch has several advantages over adding VCI directly to the base polymer. It allows for more precise control over the concentration of the corrosion inhibitors and can reduce the risk of inconsistent mixing. Additionally, it can simplify the manufacturing process and reduce the amount of VCI needed to create the desired level of protection.

EN

EN