GreenVCI®

The World-Class Anti-Corrosion & Quality Control Solution You Can Trust

Technology

What causes corrosion?

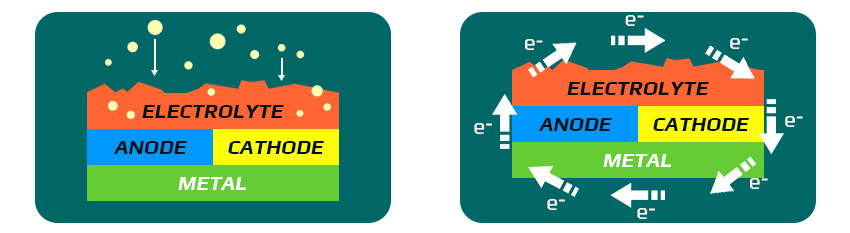

Corrosion is a natural process by which a metal returns to its original state. Corrosion takes place in an electrochemical process where electrolytes, often found in the form of humidity, cause electrons to flow from anode to cathode on unprotected metal surfaces.

- - Relative Humidity : in general, corrosion begins in RH levels of 40~70% or at temperatures above 400°C (750ºF) with presence of agents

- - Exposure to corrosion agents : chloride, fluoride, sulfides (electrolytes in general)

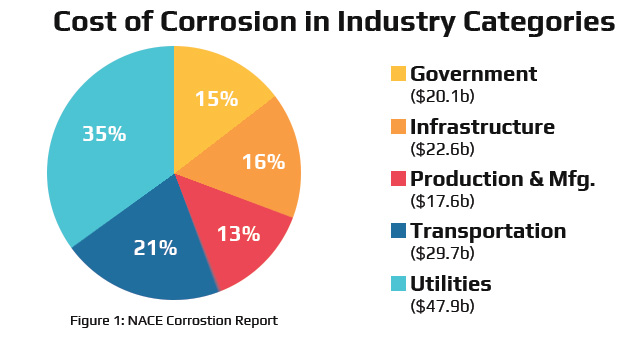

Cost of corrosion

Studies have shown that the cost of corrosion in the USA is USD 276 billion; about 3% of the GDP, according to research done by the National Association of Corrosion Engineers in the USA. Similar figures are found in the most of the industrialized nations worldwide (University of Manchester, 2015). Per industry, automotive, defense, drinking water, and sewer systems show the highest level of damage.

VCI Development History

1st Generation Products: GENERAL FUNCTIONAL VCI TECHNOLOGY

The US-government-funded research by the US Navy gave birth to VCI as a solution for preventing corrosion on military equipment during overseas shipping in World War II.

2nd Generation Products: NITRITE BASED VCI TECHNOLOGY

Still the most-used VCI is the second generation VCI, composed of nitrite and secondary amine-based chemicals. These chemicals, however, are considered carcinogenic and are becoming regulated.

3rd Generation Products: “GREEN” VCI RAW MATERIAL TECHNOLOGY

The global manufacturing industry stands on the brink of disruption as the ESG framework transforms the industry, along with other fourth industrial revolution factors such as AI, robotics, and digitization. The companies that will survive this transition will be those that protect the environment, take care of everyone involved with their products, help their communities, and have strong corporate governance. Chemical manufacturers are now under massive pressure and oversight to minimize industrial waste and carbon emissions and to come up with the most environmentally friendly yet effective products. Having anticipated this market trend well in advance, GreenVCI® has developed a full product line that meets and exceeds these requirements by incorporating readily biodegradable and food-grade-chemical-based anti-corrosion technology since the early 2000s.

VCI: Vapor/Volatile Corrosion Inhibitor

VCI is a sophisticated yet economical way of protecting metals from corrosion. When applied, the atomic layer of VCI on the surface of a metal inhibits the electrochemical process of corrosion. Our specialized eco-friendly VCI chemicals release corrosion inhibiting particles within the vapor area of a packaged metal. These VCI particles form a thin protective layer about one molecule in thickness on the surface of the metal. This invisible layer of chemicals prevents oxidization and naturally dissipates when air-flow is reintroduced. VCI chemicals artificially create covalent bonds (stable) with the metal surface to stop anode-cathode electron transmission.

- VCI creates an artificial atmosphere which prevents O, OH ions from freely moving in the closed space. VCI chemicals have a much lower vapor pressure than water (20 mmHg) at 0.01-0.4 mmHg; therefore, VCI doesn’t evaporate. VCI chemicals suspended in the air trap O, OH ions and create an artificial atmosphere which prevents rusting.

EN

EN